On the surface, there may be little difference between diamond tools. Unfortunately, many make the mistake of assuming that all diamond tools are equal and choose the least expensive option. Ironically, in the long run, this often costs customers more in wasted time and the number of tools required to finish a job. Understanding the difference between high and low-quality diamond tools will equip you with the tools, so to speak, to make an informed decision and start your next job on the right foot.

In this blog, we take a look at how the quality of diamond tools is compared and hope to offer some helpful insight for when you’re ready to purchase your next cutting tool, block saw, wire saw, floor saw, concrete hand saw, core drill, or other related equipment.

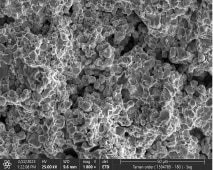

Grade and grit of diamond

Synthetic diamonds used in diamond tooling can be produced in all different shapes and sizes. Coarse diamonds are larger and tend to cost more than fine-grit diamonds. On the other hand, coarse-grit diamonds are better in quality and more effective at grinding away material.

High-grade diamonds are stronger, withstand higher temperatures and are more uniform in shape and characteristics than low-grade diamonds. High-grade diamonds will last longer and be more effective in their performance than low-grade diamonds, so they are higher in quality and contribute to a higher-quality diamond tool.

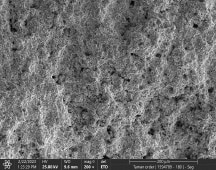

Diamond concentration

High-quality diamond tools feature a high concentration of diamonds. As the diamond is the working part of the tool, the higher the concentration of diamond in the tool, the more effective it will be.

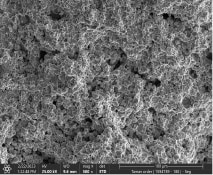

Diamond arrangement

During manufacturing, diamonds can be arranged into uniform patterns within a segment. Arranged diamond segments allow for constant contact between a diamond and the material at any given time. Tests show that arranged segments last 10-20% longer and cut 20-30% faster than non-arranged segments (when the same bond and diamond grit concentration is used). Therefore, a higher-quality diamond tool will feature an arranged cutting segment.

Bond

Concrete characteristics vary from country to country and state to state, with each aggregate significantly impacting blade performance. In some cases, when the aggregate used in the concrete is particularly ‘sharp’ and causes the segment to wear horizontally to the point that the segment width is as wide as the steel core, the tooling must be fitted with sandwich-style segment. Using a blade without the sandwich-style segment will cause the blade to jam in the cut or prematurely wear the machine. Producing the proper bond for a particular application requires years of trial and error and a specific mixture of metals. This experience and expertise lead to a higher quality, albeit higher priced, diamond tool.

Consistency

Making an excellent diamond tool once is hard, but making a great diamond tool every time is significantly more challenging. High-quality diamond tools are manufactured by companies that have internationally recognised manufacturing certificates. These certificates are awarded after rigorous testing and quality control procedures. These procedures help to ensure that there is a consistent quality between segments. This ultimately means knowing that the diamond tool will work the same every time and won’t be a letdown in its longevity or productivity.